Case Hyundai

Automotive Industry

-

Problem:

Need to track the production process.

-

Solution:

Use of Titan General RFID Tags in the production and positioning of antennas and readers for identification of parts.

-

Advantage:

Greater agility in traceability in production and in the industrial process.

-

Benefits:

Greater agility in traceability in production and in the industrial process

- Target Audience: Automotive industry

One of the solutions implemented by ACURA ensures traceability of one of the largest automotive companies in the world.

Hyundai Motor Company has set goals to provide the best consumer service, cutting-edge technology, flawless quality and the best value in the industry. Hyundai Motor Company has become one of the world's top five automakers for its continued investment in the development of futuristic concept cars that have become a benchmark of competence, technology and creativity. In April 2007 the Hyundai Caoa Carmaker is inaugurated in the city of Anápolis (GO), and the production of the HR truck begins.

SOLUTION_DETAILS

-

Client:

Hyundai Motor Company has set goals to provide the best consumer service, cutting-edge technology, flawless quality and the best value in the industry. Hyundai Motor Company has become one of the world's top five automakers for its continued investment in the development of futuristic concept cars that have become a benchmark of competence, technology and creativity. In April 2007 the Hyundai Caoa Carmaker is inaugurated in the city of Anápolis (GO), and the production of the HR truck begins.

-

Proposed Challenge:

Track the production process, avoiding material losses and delays in production steps.

-

Equipment:

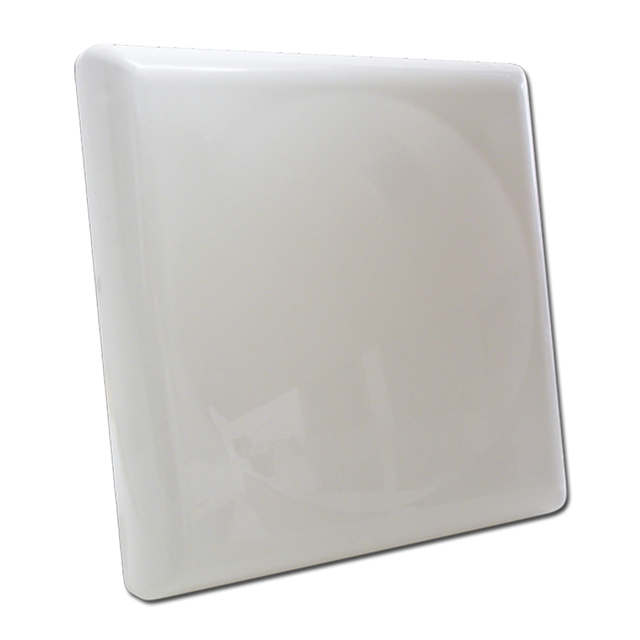

UHF M6 Player, UHF Titan General Tags and Compact Monostatic Antennas.

-

Solution:

Use of RFID Tags Titan General, which is able to support the automotive operation, meeting the specific standards, in the items of production and positioning of antennas and readers for identification of parts.

-

Operation:

The tag is applied on the parts. When the part passes through the antenna, it sends a signal identifying the part and its position in the production process, expediting the material conference avoiding losses and delays.

-

Differentials / Practical Improvements:

With this automated system, the presence of personnel to monitor the production process is avoided.

-

Gains / Benefits:

Material losses and time in process traceability are avoided, thus increasing safety.

PRODUCTS_RELATED

-

EDGE-50 TCP-IP cod. 100.255

-

UHF Antenna MTI Mono Circular 7 cod. 100.322